Front-loading kilns, ovens, and furnaces are a fantastic alternative for a variety of industries and applications due to their numerous advantages, In fact we think they're one of the best...

Front-loading kilns, ovens, and furnaces are a fantastic alternative for a variety of industries and applications due to their numerous advantages, In fact we think they're one of the best choices around!.

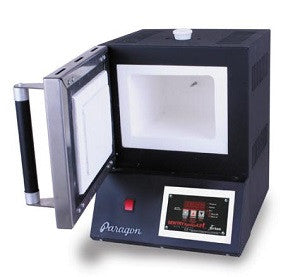

Better Accessibility and Faster Loading and Unloading: One of the main benefits of front-loading kilns is how quickly and easily materials can be loaded and unloaded. The kiln's layout makes chamber access simple, which simplifies the whole process for operators. This increases productivity overall and saves critical time. The enhanced accessibility for the front-loading kiln also facilitates service and maintenance duties, minimizing downtime and ensuring the kiln is kept in good working order.

Improved Temperature Uniformity: Front-loading kilns are renowned for their superb temperature consistency inside the chamber. Performance is greatly improved by kiln's uniform heat distribution. The high temperature kiln makes sure that all materials are processed under the same conditions, producing results that are reliable consistent. This feature is essential for delivering high-quality results and adhering to exact specifications, whether it is used to heat treat metals or fire ceramics.

Greater Capacity: Front-loading kilns and ovens have larger door openings and deeper chambers, which result in an important boost in capacity. The open layout enables bigger loads, allowing the processing of larger amounts of material in a single batch. Because it decreases the number of firings needed this increases overall productivity. This larger capacity is especially advantageous to businesses with high production demands.

Increased Safety: Front-loading kilns use a swing-out door to address safety, which is a top priority in any industrial setting. Due to its great interior visibility, the swing-out door improves safety during loading and unloading procedures. The potential of accidents or injuries is reduced because front-loading kiln operators may observe the operation without having to reach far within the kiln. By ensuring a safer working environment, this feature protects both the workers and the materials being processed.

Enhanced Process Monitoring: The interior of the high temperature kiln is easily accessible, which increases safety and facilitates better process monitoring. Operators may keep a close eye on the materials and how they change, ensuring that the conditions are stable and that any deviations are immediately found and fixed. With superior control over the entire heating or firing process attributable to this real-time monitoring capability, accurate and repeatable outcomes are produced.

Applications Flexibility: Front-loading kilns are flexible and have uses in a variety of sectors, including ceramics, glass-making, metallurgy, and the processing of sophisticated materials. These industrial kilns are essential tools for research, industrial, and artistic endeavors because of their versatility with regards to materials and processes.

Choosing a front-loading kiln, oven or furnace is an excellent option for consistency, efficiency, and safety. These heat treat kilns have quicker loading and unloading times, expanded capacity, uniform temperature, improved accessibility, and improved safety measures guarantee efficient operations and excellent outcomes. Front-loading kilns are still a dependable and valuable asset in a variety of applications, whether they are employed in laboratories, manufacturing facilities, or artistic studios.

Heat Treat Now’s commitment to deliver quality heat treating kilns is unmatched. Every front-loading kiln is built with superior quality at the forefront so that our products deliver the results you need year after year. Whether you're just getting started, looking to purchase another industrial kiln, or seeking to upgrade your equipment, shop our inventory now or contact us today!