Laboratory and testing kilns have numerous benefits, making them an excellent option for a variety of users, including scientific and research applications.Accurate Laboratory Oven Temperature Control: Engineers, researchers, and scientists...

Laboratory and testing kilns have numerous benefits, making them an excellent option for a variety of users, including scientific and research applications.

Accurate Laboratory Oven Temperature Control: Engineers, researchers, and scientists can maintain accurate and stable temperature settings due to laboratory and testing kilns' superior temperature control systems. Utilizing a laboratory oven for drying to remove binders ensures this level of control, which is essential for conducting precise tests, material testing, and thermal analysis.

Even Temperature Distribution: By removing fluctuations in temperature that can jeopardize the integrity of test samples, these kilns provide even temperature distribution throughout the chamber. For accurate and repeatable outcomes in a variety of testing processes, a stable temperature environment is essential.

Utilization Flexibility: Laboratory ovens and testing kilns can be used for various tasks. Laboratory kilns are utilized in numerous scientific sectors, including material research, biomedical research, chemical synthesis, ceramics testing, and many more. The flexibility of the smaller, more compact, laboratory kiln makes them vital tools in research laboratories because of their versatility to various materials and testing procedures.

Controlled Atmosphere Options: such as oxidizing, reduction, or inert conditions, are available with some laboratory kilns and laboratory ovens. This function proves essential for exploring certain chemical processes, replicating real-world events, and analyzing material behavior under specific gas circumstances.

Customizable Heating Profiles: Modern laboratory kilns include programmable controls that let users design customized heating profiles. The ability to precisely configure temperature ramps hold periods, and cooling rates in a laboratory drying oven enables researchers to model complex thermal processes and investigate material responses in dynamic environments.

Data Logging and Analysis: Many contemporary laboratory kilns and laboratory ovens have data logging features that allow for constant temperature monitoring and recording, among other crucial factors. The data from the laboratory oven can then be analyzed to learn important things about how materials behave in various tests and studies.

Safety features: Safety is taken into consideration when designing laboratory kilns and laboratory ovens. To minimize mishaps and maintain the safety of laboratory staff, they frequently include features like over-temperature protection, door interlocks, and additional insulation.

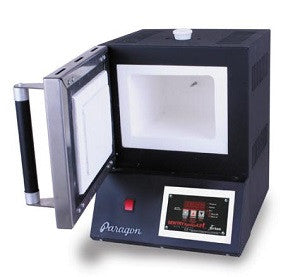

High-Quality Construction: To resist intensive wear in research contexts, laboratory and testing kilns are built using high-quality materials. Even in severe circumstances, these laboratory kilns' robust builds guaranty endurance and dependable performance.

Simple Maintenance and Calibration: Due to their design and user-friendly features, laboratory kilns and laboratory ovens often require minimal maintenance and calibration. Accurate temperature readings and trustworthy outcomes are ensured by routine calibration. Calibration certificates are available upon request.

Adherence to Industrial Standards: Many laboratory kilns follow industrial norms, ensuring that the research and testing carried out in these kilns are of the required high caliber and precision. UL and CE-tested certified units are available.

The bottom line is that laboratory and testing kilns provide accurate temperature control, uniform temperature distribution, diversity in applications, controlled environment options, programmable heating profiles, data logging capabilities, safety features, high-quality construction, and ease of maintenance. These characteristics make laboratory kilns essential instruments in research and scientific labs, giving researchers the control and dependability they need to perform accurate experiments and tests across various fields.

Examples of uses for Laboratory Kilns and Ovens are: Dental Labs for curing dental ceramics, crowns, bridges, implants, dentures, and other dental porcelain, zirconium products. Tool & Die Shops: These units are used by engineers and tradesman in various metal fabrication shops for heat treating small items such as screws, bolts, rivets, dies, and other machine made or cast parts.